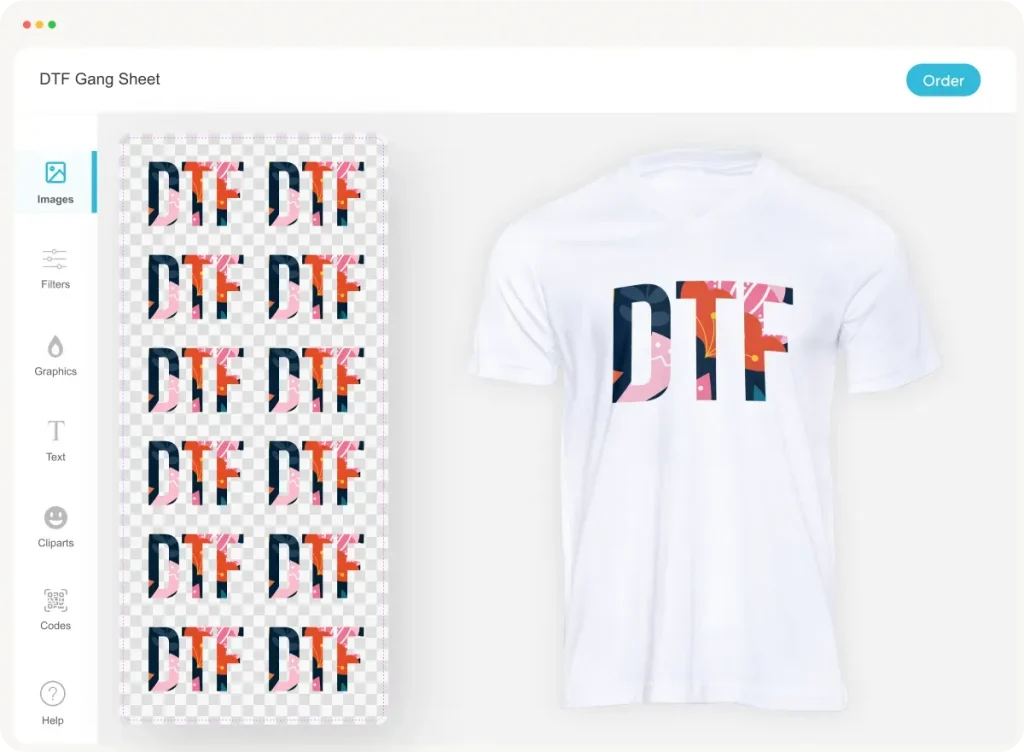

DTF Gangsheet Builders are revolutionizing the textile printing industry, making it easier for businesses to achieve vibrant, high-quality designs on a variety of fabrics. This innovative DTF (Direct-to-Film) printing method allows for multiple images to be printed on a single sheet, optimizing efficiency and minimizing waste. In this engaging guide, you will discover essential techniques and practices, including a comprehensive DTF printing tutorial that addresses how to use DTF gangsheet effectively. Whether you’re a seasoned professional or just starting, mastering DTF gangsheet builders can significantly enhance your printing output while reducing costs. Let’s dive in and explore the best practices for DTF printing that will take your custom apparel to the next level.

In the realm of custom apparel production, utilizing gangsheet builders for DTF printing offers a host of advantages. This advanced textile printing technique, which stands for Direct-to-Film, involves transferring intricate designs directly onto fabrics, combining multiple graphics into a single cohesive print run. This streamlined approach not only boosts productivity but also fosters creativity by allowing for endless design configurations. Within this guide, you’ll learn about various DTF printing strategies, essential materials needed, and detailed processes that will guide you through creating stunning prints. By employing these methods, you can elevate your printing projects while adhering to best practices for the highest quality results.

Understanding DTF Printing Technology

DTF printing technology, or Direct-to-Film printing, has become highly revered in the world of fabric decoration due to its versatility and exceptional results. This method allows for direct transfer of intricate designs onto textiles, making it distinct from traditional techniques like screen printing. The process involves printing designs onto a specialized film and applying an adhesive that bonds the print securely to the fabric. The result is a vibrant, durable print that maintains its quality after numerous washes.

The beauty of DTF printing lies in its ability to work with a variety of fabrics, including cotton, polyester, and blends. This can be particularly advantageous for custom apparel creators and small business owners looking to offer a wide array of products without investing heavily in multiple printing methods. By mastering the DTF process, printers not only ensure high-quality outputs but also maximize operational efficiency through gangsheet techniques that minimize waste and costs.

Essential Materials for DTF Gangsheet Printing

To begin your journey with DTF gangsheet printing, having the right materials is crucial. First and foremost, investing in a high-quality DTF printer that is compatible with DTF inks ensures that your prints are vibrant and precise. It’s recommended to use models from reputable brands like Epson and Mimaki. These printers are specifically engineered to handle the unique requirements of DTF printing, offering superior results compared to standard inkjet models.

Additionally, the quality of your transfer films and adhesive powder can significantly impact the final product. When it comes to transfer films, high-grade options will provide better ink adhesion and color saturation. Moreover, the adhesive powder must be evenly applied to ensure thorough bonding. Having a reliable heat press with adjustable settings also helps to achieve the perfect temperature and pressure for effective transfers.

Step-by-Step Guide to Mastering DTF Gangsheet Builders

Embarking on your DTF printing adventure starts with creating your designs thoughtfully. Utilizing software tools like Adobe Illustrator, you can craft intricate vector designs that will maximize space on your gangsheet. This stage is vital; the placement and sizing of each design on the gangsheet must be done carefully to optimize printing efficiency. Consider the materials you will print on, as this can influence color choices and overall design elements.

After completing your designs, the next phase is setting up your printer. Proper calibration and resolution settings are essential for achieving the best print quality. Loading the DTF film correctly and aligning it in your printer minimizes the risk of misprints. Following this, applying the adhesive powder right after printing helps ensure your designs adhere well to the fabric during the transfer process.

Best Practices for Efficient DTF Printing

Practicing efficient DTF printing goes beyond just following the steps; it involves intentional techniques that enhance your production. Conducting test prints is an excellent way to verify your colors and adhesion before moving onto larger batches. This practice can save you valuable materials and time, allowing you to evaluate how different fabrics react to the printed designs and adhesive processes.

Moreover, maintaining your equipment is paramount in ensuring consistent quality output. Regular cleaning of printer heads prevents clogging that can occur from dried inks, while a well-maintained heat press allows for optimal transfer conditions. Keeping abreast of the latest advancements in the DTF industry, such as new inks and methodologies, can also elevate your printing outputs, giving you a competitive edge in the market.

Exploring Different Fabrics for DTF Printing

One of the significant advantages of DTF printing is its adaptability to various fabric types. From cotton to polyester blends, each material can produce different aesthetic effects when printed using DTF techniques. As such, it is essential for printers to experiment with different fabrics to understand how each performs during the printing and transfer processes. This exploration can lead to discovering unique products that cater to specific market niches.

Testing your designs on varied textures and materials also allows for innovation in your product offerings. By documenting the results of your experiments and noting which combinations yield the best outcomes, you can refine your processes and enhance your repertoire. Ultimately, understanding fabric behavior is vital for producing high-quality prints that meet consumer expectations.

Staying Updated in the DTF Printing Community

The realm of DTF printing is rapidly evolving, with constant developments in technology and techniques. To stay competitive and informed, it is vital for printers to engage with online communities, forums, and training sessions that focus on DTF printing. These environments foster learning and knowledge-sharing, allowing users to exchange tips, experiences, and best practices.

Moreover, staying connected with industry influencers and subscribing to relevant publications can help you stay abreast of the latest trends. Such insights can inform your approach to DTF printing, from choosing materials to implementing new techniques that enhance your efficiency and print quality. Embracing ongoing education in DTF printing ensures that your skills and practices remain current and competitive.

Frequently Asked Questions

What are the best practices for DTF gangsheet builders?

Best practices for DTF gangsheet builders include conducting test prints for color accuracy and adhesion, regularly cleaning printer heads and heat presses, staying updated with the latest DTF printing techniques, and experimenting with different fabrics to discover what works best for your printing business.

How do I properly use a DTF gangsheet in my printing process?

To properly use a DTF gangsheet, start by designing your graphics in vector format to fit within standard gangsheet sizes. Print the designs on DTF transfer films, apply the adhesive powder, cure it, and finally transfer the designs onto the fabric using a heat press at the right temperature and pressure settings.

What equipment do I need for effective DTF gangsheet printing?

For effective DTF gangsheet printing, you need a dedicated DTF printer, high-quality transfer films, adhesive powder, a heat press with adjustable settings, and graphic design software like Adobe Illustrator or CorelDRAW to create your designs.

What is the main advantage of using DTF printing techniques compared to traditional methods?

The main advantage of using DTF printing techniques is the ability to adhere designs to a wide variety of fabrics while maximizing efficiency through gangsheet building, which minimizes material waste and saves costs compared to traditional printing methods.

Where can I learn more about DTF printing tutorials and techniques?

You can learn more about DTF printing tutorials and techniques through online resources, videos, and communities dedicated to DTF printing, as well as by attending workshops or webinars that focus on mastering DTF gangsheet builders.

Can DTF gangsheet builders optimize my printing business?

Yes, mastering DTF gangsheet builders can optimize your printing business by allowing for the efficient production of multiple designs on a single sheet, reducing waste, and enhancing the quality of the finished products that can appeal to a wider range of customers.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A process of printing designs onto a special film and transferring it onto textiles; it allows for vibrant prints on various materials through the gangsheet technique. |

| Key Materials Needed | 1. DTF Printer (Epson or Mimaki recommended) 2. High-quality Transfer Films 3. Adhesive Powder 4. Heat Press with adjustable settings 5. Graphic Design Software (Adobe Illustrator, CorelDRAW) |

| Step-by-Step Tutorial Overview | 1. Design Creation: Use vector format in graphic software. 2. Printer Setup: Load inks and set parameters. 3. Applying Adhesive: Sprinkle powder on wet prints. 4. Transfer Process: Heat press cured film onto fabric. 5. Cooling and Peeling: Allow cooling before peeling off the film. |

| Best Practices for DTF Printing | – Conduct Test Prints for accuracy. – Regularly maintain printer heads and heat press. – Stay informed on industry trends. – Experiment with different fabrics for unique effects. |

Summary

DTF Gangsheet Builders are essential for modern textile printing, enabling custom apparel makers to produce high-quality designs efficiently. This comprehensive guide outlines how to master the DTF printing process, from understanding the technology to executing the intricate steps involved in creating gangsheet prints. By focusing on quality materials, adhering to best practices, and keeping up with industry advancements, you can optimize your printing operations and expand your creative offerings. The journey through DTF gangsheet printing not only enhances your production capabilities but also enriches your connection with customers by delivering vibrant, customized apparel that meets diverse demands.