DTF transfers, short for Direct-to-Film transfers, have emerged as a revolutionary technique in the garment printing industry, championed for their vibrant colors and high adaptability. However, many users encounter pitfalls that can lead to printing errors and dissatisfied customers. Understanding and avoiding common mistakes using DTF prints is essential for achieving the best results possible. This guide will delve into crucial DTF transfer tips, ensuring that you are well-equipped to maximize the potential of this innovative printing method. By implementing best practices for DTF transfers, you can significantly improve the durability and quality of your prints, enhancing your overall printing experience.

Direct-to-Film transfer techniques offer a modern twist on garment decoration, enabling crisp and colorful designs to fuse seamlessly onto various fabrics. As the demand for high-quality prints grows, so does the necessity to grasp effective methods for utilizing these transfer systems successfully. Exploring how to use DTF transfers effectively can help you avoid common DTF printing errors and maximize the potential of your designs. With insights into preparation, material selection, and post-transfer care, you can easily elevate your garment printing projects. Adopting industry best practices is key to ensuring your creations stand out and last.

Understanding DTF Transfer Basics

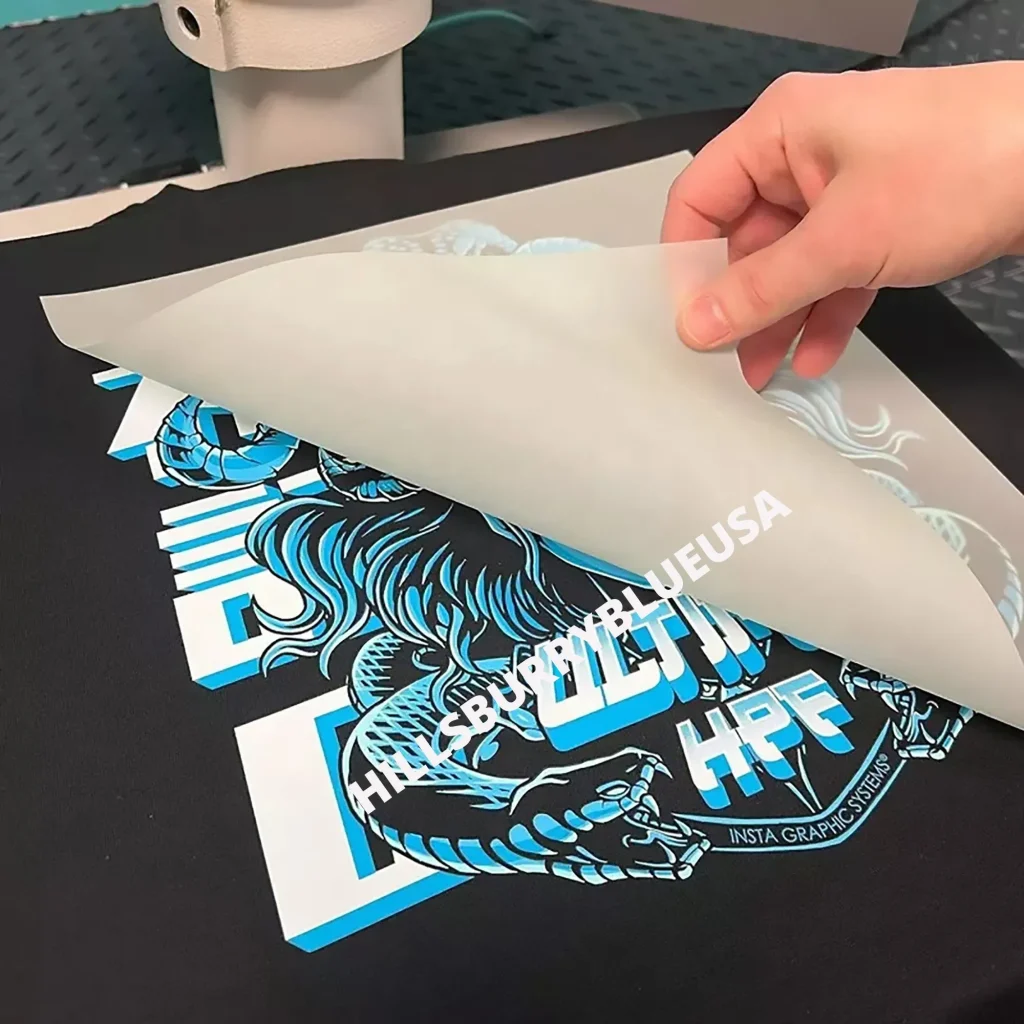

Direct-to-Film (DTF) printing is a revolutionary method that allows for vibrant and intricate designs on various fabrics. This technique involves printing an image onto a special film, which is then transferred to the garment with heat and pressure. However, before diving into the DTF printing process, it’s essential to familiarize yourself with the basics. Knowing how DTF transfers work and what materials are required is crucial. A well-rounded understanding of these fundamentals will not only enhance your printing skills but also prevent costly mistakes down the road.

The success of DTF printing lies in selecting the right combination of ink and film. Each type of ink works best with particular films, which in return affects the saturation and durability of the print. As a beginner, it’s a good practice to experiment with various products until you find the right match for your specific needs. Familiarize yourself with the specifications and requirements of your printing setup to ensure optimal results and to mitigate common errors associated with DTF transfers.

Common Mistakes Using DTF Transfers

Avoiding mistakes is fundamental in achieving the best results with DTF transfers. One prevalent error is failing to prepare design files correctly. Users often overlook the importance of setting their images to the correct resolution, which can lead to pixelation and overall reduced print quality. It’s recommended to set your files at a minimum of 300 DPI to ensure crisp and clear prints. By investing time in proper file preparation, the chances of errors diminish significantly.

Another common pitfall is neglecting ink and film compatibility. New users may not realize that not all inks work well with the same film types, which can lead to lackluster results or printing errors. Conduct thorough research to ensure you’re pairing the right ink with the correct film to achieve those vibrant, eye-catching prints that DTF is known for. Additionally, investing in quality supplies will yield much better outcomes than opting for cheaper, incompatible materials.

Best Practices for DTF Transfers

When it comes to DTF transfers, adhering to best practices can significantly enhance the quality of your prints. For instance, maintaining proper temperature and pressure settings is vital during application. Many users overlook this step, but each project will require specific settings based on the materials used. Always refer to the manufacturer’s guidelines to determine the optimal settings for your printer and transfers, ensuring a smooth application process and quality results.

In addition, proper post-transfer care is essential for prolonging the life of your DTF prints. Ignoring washing instructions or curing times can lead to premature wear and fading, drastically reducing the lifespan of your design. As a rule of thumb, allow ample time for your prints to cure and always wash garments inside out with cold water. Following these best practices will help you create durable, long-lasting prints that maintain their vibrancy over time.

DTF Transfer Tips for Beginners

For those new to DTF printing, having a set of helpful tips can make the learning process smoother. One important tip is to invest in high-quality DTF supplies, including both ink and film. Cheap materials can compromise the integrity of your prints, leading to frustration and disappointment. As you become more comfortable with the process, experiment with different combinations until you find what works best for your printing style.

Additionally, don’t shy away from seeking education and resources on DTF printing. Numerous tutorials and guides exist, offering insights on how to use DTF transfers effectively. Engaging with communities, reading blogs, and watching video tutorials can provide invaluable advice that can help you avoid common mistakes that beginners often make. Sharing experiences with others also opens the door to discovering unique methods and techniques that can enhance your printing outcomes.

Addressing DTF Printing Errors

DTF printing errors can be frustrating, but understanding their causes is the first step to improving your results. Many users face issues such as incomplete adhesion or color inconsistency, often stemming from incorrect temperature or pressure settings. Regularly testing your equipment and referring to guidelines can help you troubleshoot problems before they affect your prints, allowing for a more seamless production process.

In addition, keeping your printing equipment clean and well-maintained can prevent many common errors associated with DTF transfers. Dust, ink residue, and wear can lead to poor print quality, so dedicate time to maintaining your machinery. Regular maintenance checks can help identify potential issues early on, ensuring that quality remains high throughout your printing endeavors.

Storage Solutions for DTF Transfers

Proper storage of DTF transfers is crucial for maintaining their quality and readiness for use. Many beginners overlook this aspect, which can lead to creases or marks that adversely affect print output. Ensure that you store transfers flat in a cool, dry environment to prevent any damage. This simple step of ensuring an optimal storage condition can greatly improve the longevity and performance of your DTF films.

Moreover, consider investing in storage solutions specifically designed for transfer films. This might include files or containers that protect against humidity and physical damage. By prioritizing how you manage and store your prints, you’ll ensure that every transfer is ready for use without concerns about quality degradation, leading to more successful projects overall. Small actions like these can set the foundation for a successful printing operation.

Frequently Asked Questions

What are the top mistakes to avoid when using DTF transfers?

When using DTF transfers, avoid neglecting proper file preparation, using incorrect ink and film choices, setting improper temperature and pressure, ignoring post-transfer care, and mismanaging transfer storage. Each of these mistakes can significantly affect the quality of your prints.

How do I properly prepare files for DTF transfers?

To properly prepare files for DTF transfers, ensure your images are high-resolution (300 DPI) and saved in PNG format with transparent backgrounds if applicable. This will prevent pixelation and enhance the final print quality.

What are some best practices for DTF transfer printing?

Best practices for DTF transfer printing include using high-quality inks and films designed for compatibility, setting accurate temperature and pressure levels according to manufacturer guidelines, and allowing proper curing times for the prints.

How can I avoid DTF printing errors?

To avoid DTF printing errors, double-check your file specifications, choose compatible ink and film, maintain proper temperature and pressure settings during printing, and follow the recommended care instructions after the transfer is applied.

What tips can improve my DTF transfers?

Enhance your DTF transfer results by regularly maintaining your printing equipment, experimenting with different materials and settings, and ensuring proper storage of transfers to prevent damage.

How should I care for my DTF printed garments?

Care for DTF printed garments by allowing the transfers to cure sufficiently before washing, washing inside out in cold water, and avoiding harsh detergents to maintain the vibrancy and longevity of your prints.

| Mistake | Why it Matters | Best Practices |

|---|---|---|

| Neglecting Proper File Preparation | Low-resolution images can lead to pixelation and blurriness in the final print. | Use high-resolution images (300 DPI) and PNG files with transparent backgrounds when possible. |

| Incorrect Ink and Film Choices | Wrong combinations can lead to dull colors and poor adhesion. | Invest in compatible DTF films and conduct thorough research before purchasing. |

| Improper Temperature and Pressure Settings | Insufficient heat or pressure can cause incomplete adhesion or damage. | Refer to manufacturer guidelines to set the correct parameters and test on similar fabrics. |

| Ignoring Post-Transfer Care | Skipping proper care can lead to fading and wear. | Cure transfers as recommended and wash garments inside out in cold water. |

| Mismanagement of Transfer Storage | Improper storage can create creases or marks that affect the print. | Store transfers flat in a cool, dry environment with low humidity. |

Summary

DTF Transfers are a revolutionary method in the world of garment printing, allowing for vibrant and detailed designs to be transferred onto various fabrics. By avoiding the top 5 mistakes highlighted in this guide, users can significantly enhance their printing quality and satisfaction. Proper file preparation, correct material choices, accurate temperature and pressure settings, diligent post-transfer care, and appropriate storage practices play crucial roles in achieving the best results. Ensuring that these elements are meticulously managed will lead to stunning prints that not only attract customers but also stand the test of time. For garment printers looking to improve their craft, mastering these essential practices related to DTF Transfers is indispensable.